Product Center

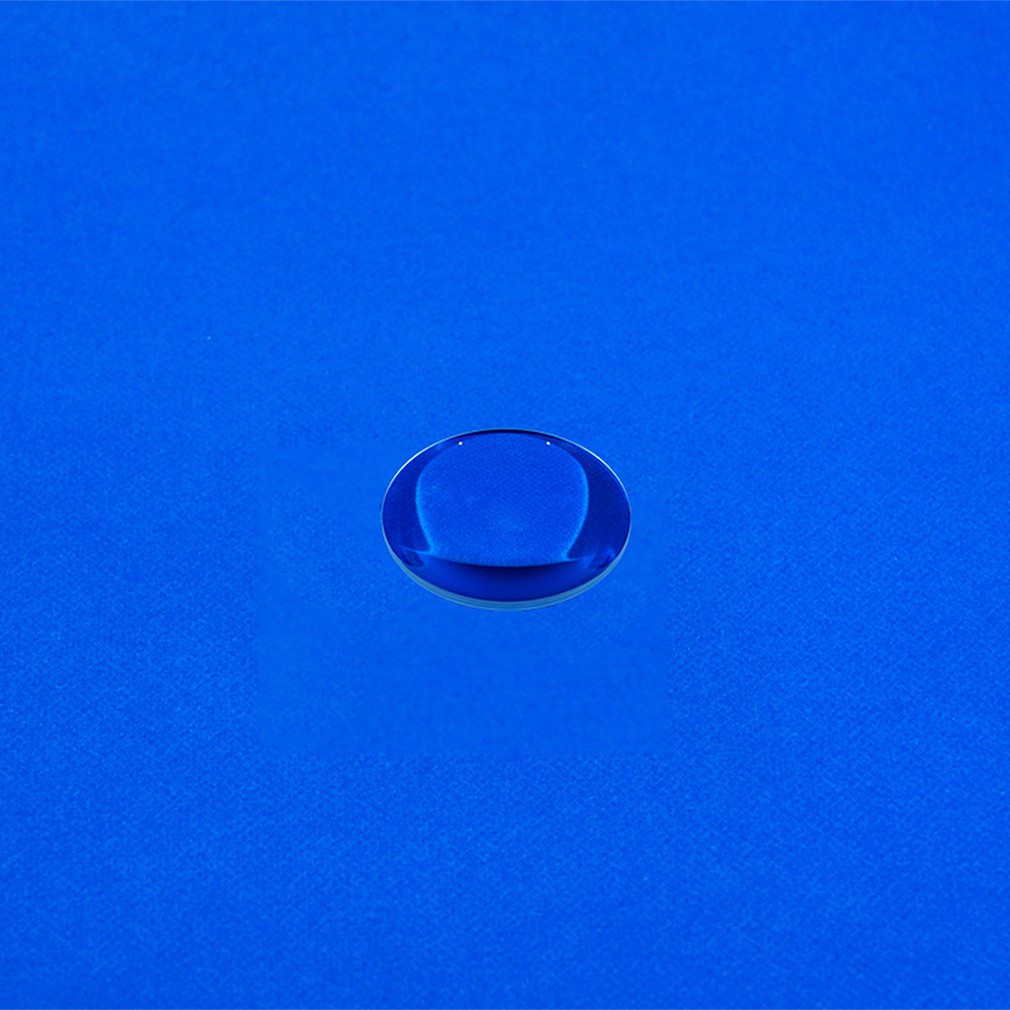

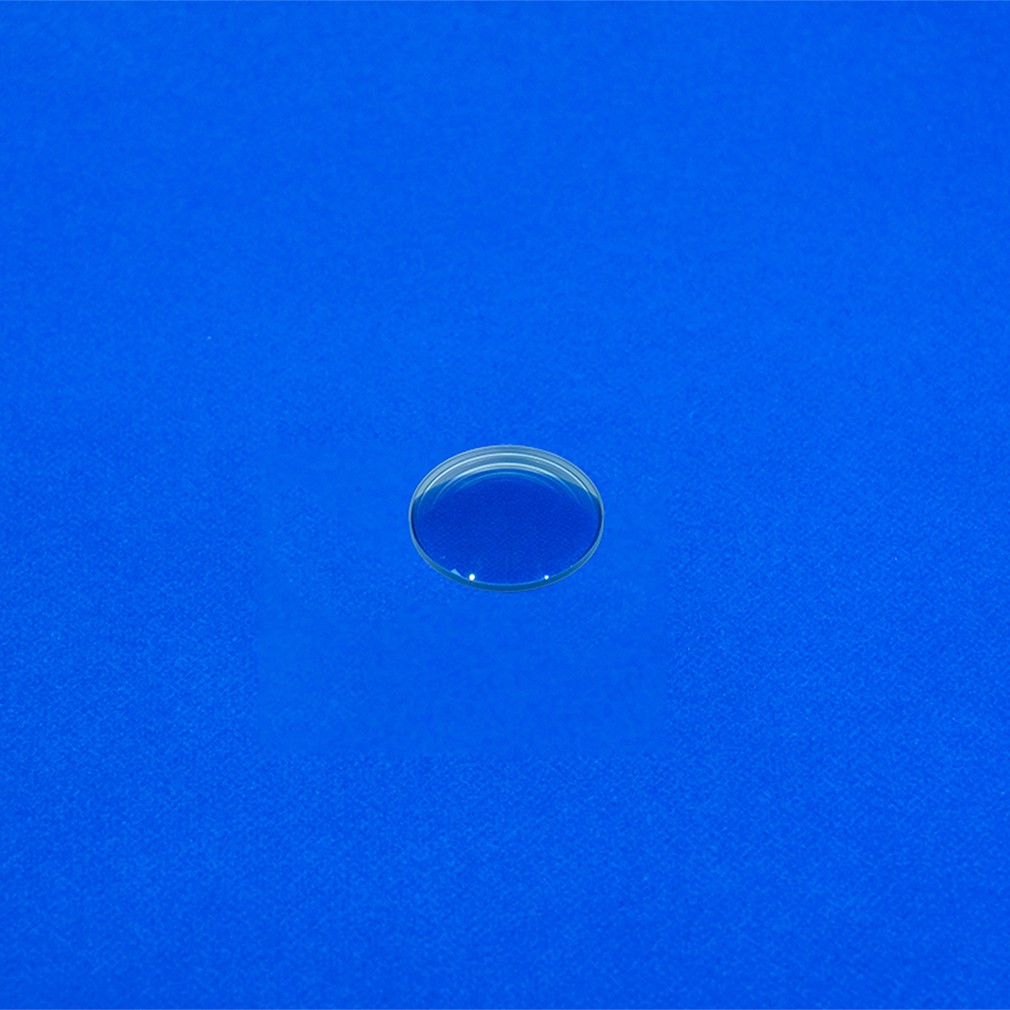

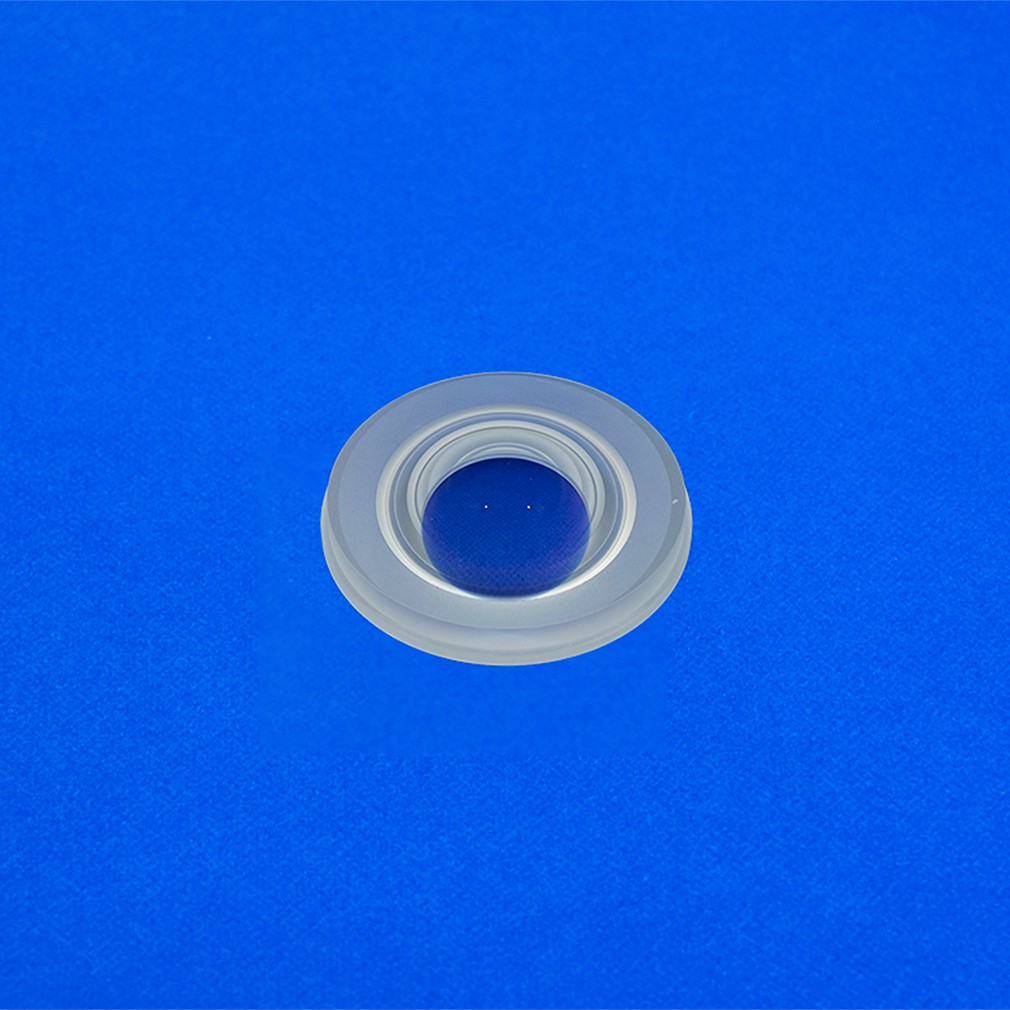

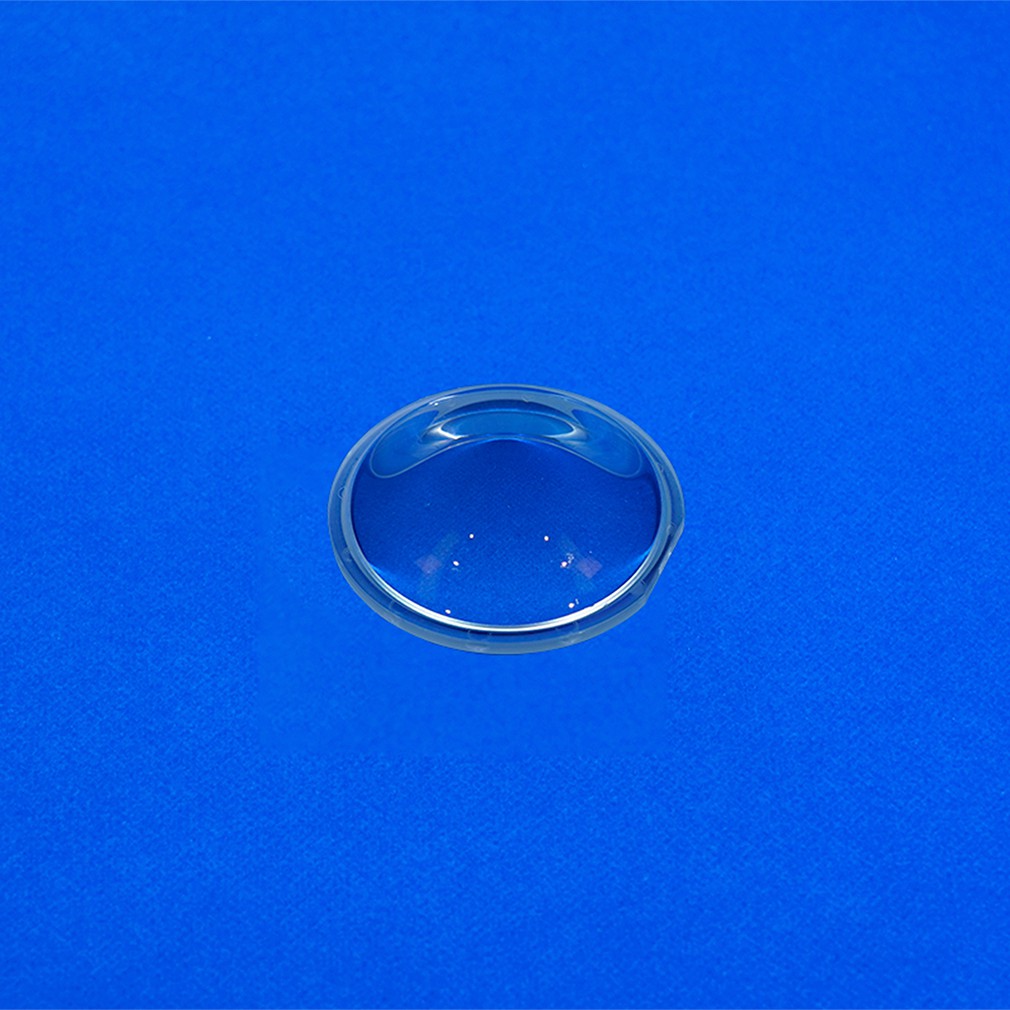

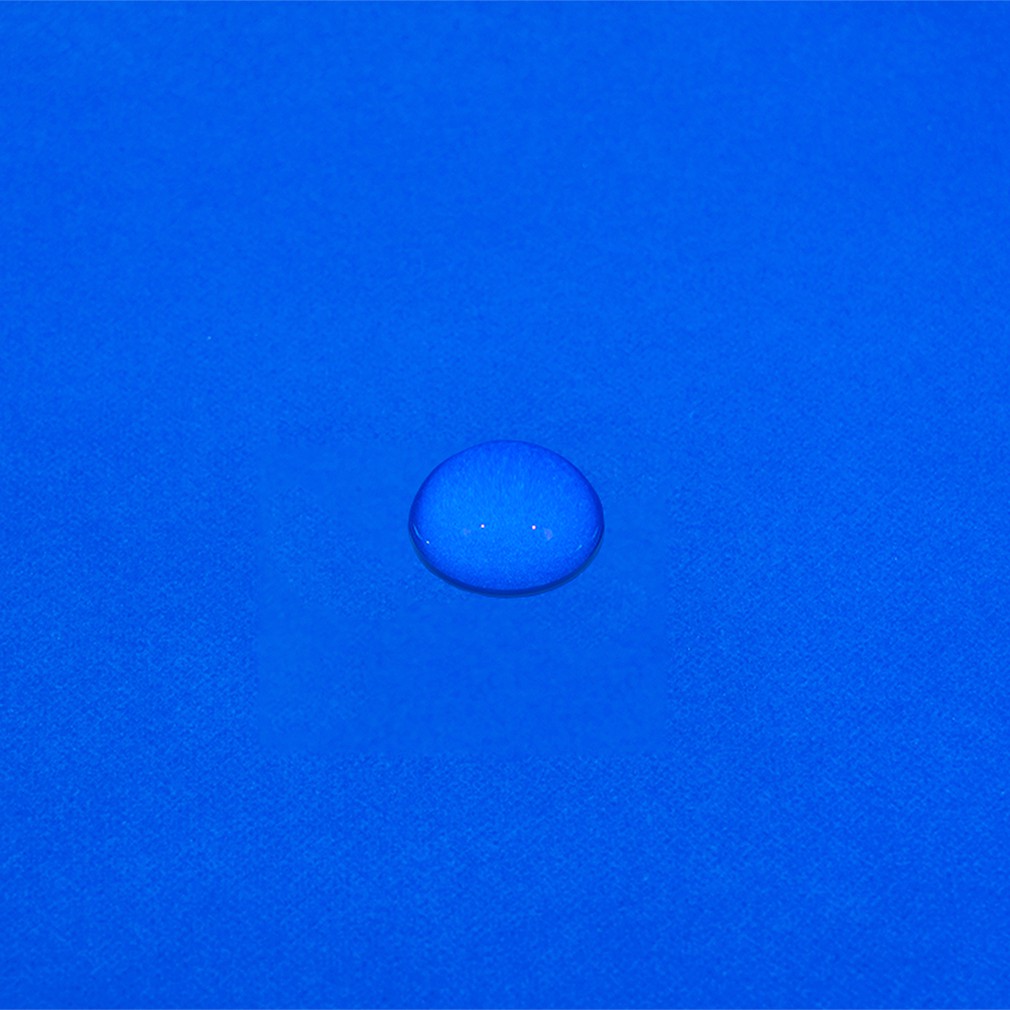

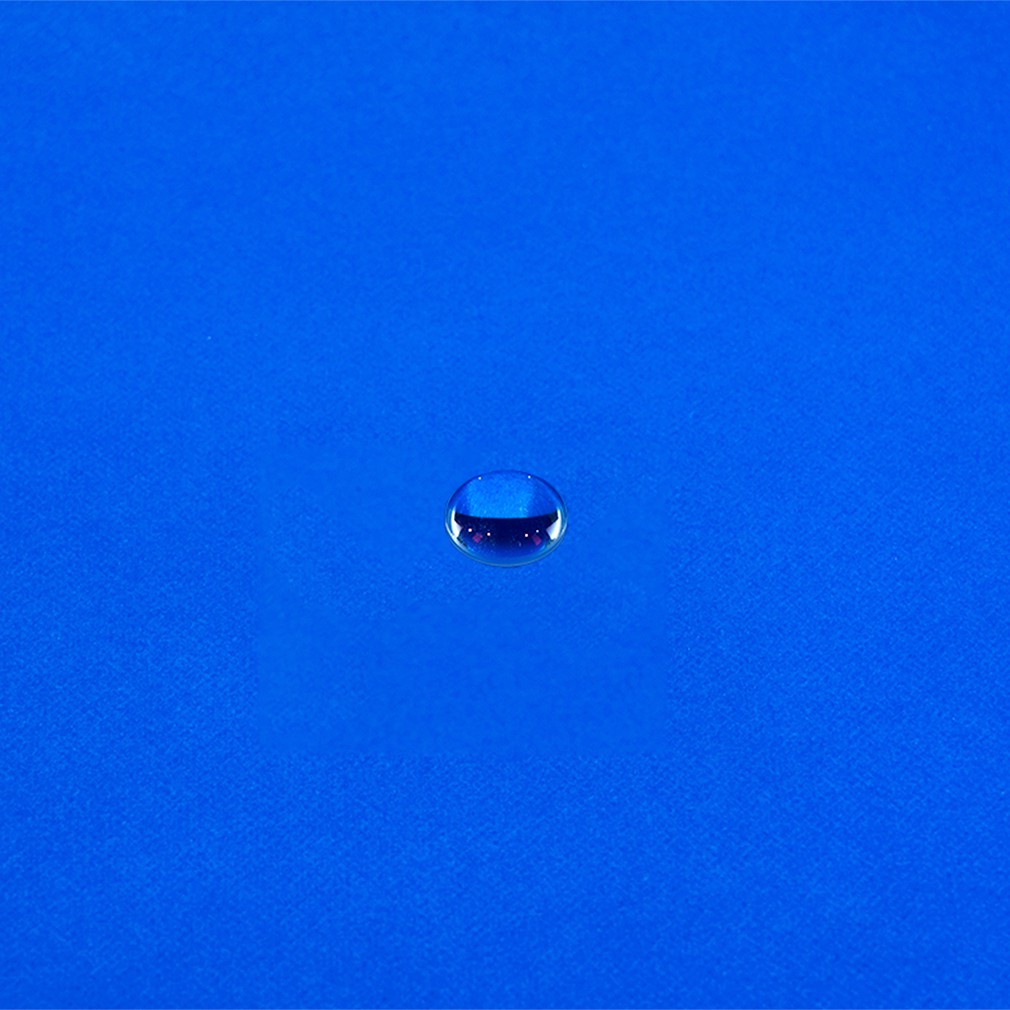

Single Lens

Technical Specifications

Outer Diameter: 5 - 230 mm

Diameter Tolerance: ≥ ±0.008 mm

Center Thickness Tolerance: ≥ ±0.01 mm

Newton's Rings (N): ≥ ±1

Irregularity (ΔN): ≥ 0.3

Surface Figure: λ/6

RMS: ≥ 0.15

Transmission Decentration: ≥ 10 arcsec

Reflection Decentration: ≥ 30 arcsec

Surface Quality: 20-10 (per MIL-PRF-13830B)

Material: Material Abrasion Degree: 50 - 510 (Includes: FCD10A, FCD100, FD225, E-FDS3, FDS20-W, PCD51, FD225, TAF3D, PCD4, NBFD3, NBFD13, NBFD10, TAF5, TAFD5F, Fused Silica/Quartz, etc.)

Coatings:

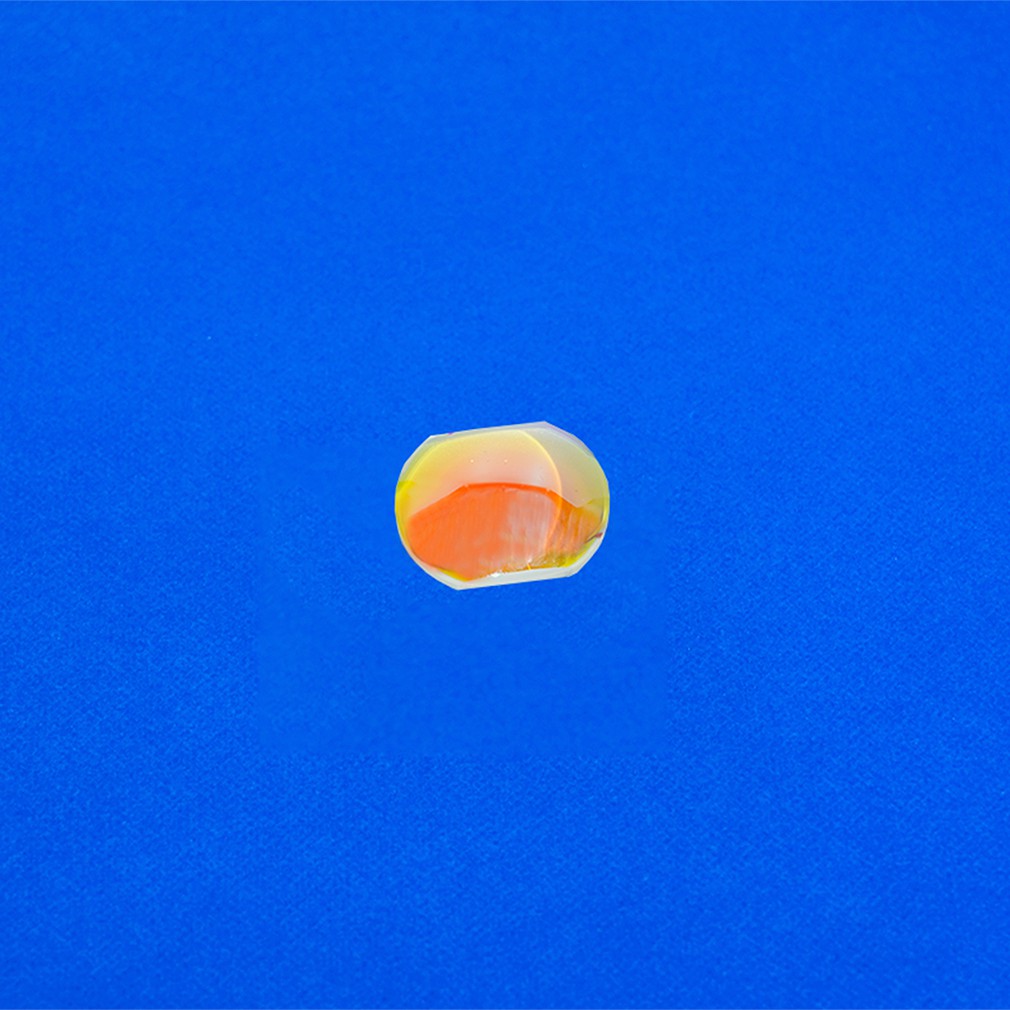

AR Coating (Anti-Reflective Coating): 400 - 1000 nm. Effectively reduces stray light for superior imaging. Primarily used for projection lenses, camera lenses, and photographic lenses.

Laser Coating: 420 - 680 nm, Dual-band for 532 nm & 1064 nm. Withstands high-power laser irradiation without damage. The former (420-680nm) is mainly used for high-end laser projection; the latter (532/1064nm) is primarily used for medical equipment.

Super Hard Water-Repellent Coating: 400 - 900 nm. Features high abrasion resistance and strong hydrophobicity. Effectively reduces stray light for clear imaging. Mainly used for high-end surveillance lenses, automotive lenses, etc.

UV/IR Coatings: 400 - 700 nm. Cut-on/off wavelength T=50%, ±5 nm. Enhances transmission in desired wavebands while blocking unwanted ones. Primarily used for various waveband applications in equipment and instruments.

Note: Various specifications can be customized according to customer requirements.